Miter Gear 20° Pressure Angle Miter Gear 20° Pressure Angle Steel-Flat Hole-Unhardened Pitch Pitch 8 Pitch 10 Pitch Miter Gear 20° Pressure Angle Steel-Flat Hole-Unhardened Teeth 12 Pitch 14 Pitch 16 pitch 20 pitch 24 pitch mitre gear 20° pressure angle-flat...

Miter gear

20° pressure angle

|

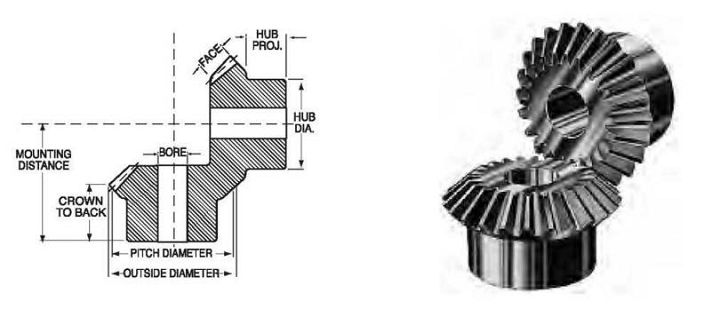

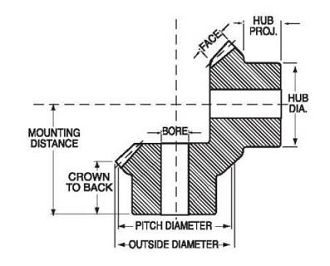

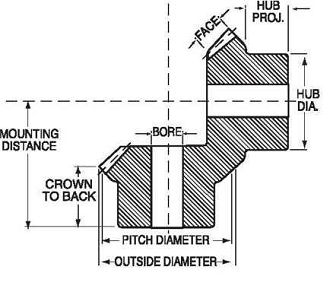

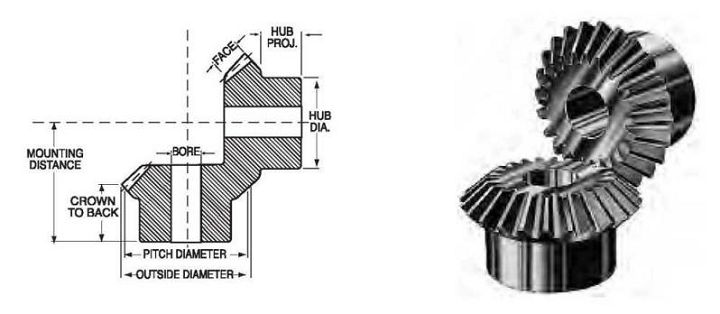

Helical gears are usually used as right angle drives, Transmission of horsepower between intersecting shafts In a 1:1 ratio.They are used where efficiency is high Need.There are only miter joints with the same number of teeth and spacing, And pressure angle can be operated together.Over Two miter joints can be used in sets, just like in a differential. The thrust of the helical gear causes the gears to separate; Therefore, ball bearings or roller bearings should Instead of sleeve bearings. The use of thrust bearings should be specified Absorb the backward thrust. All standard stock helical gears must be installed in Right angle (90 degrees) to get the correct gear bearing. All mitre gears and bevel gears are used Coniflex tooth profile. Allow slight gear misalignment Due to partial gear bearing operation Along the longitudinal direction of the gear teeth. |

The installation distance must be kept to maintain Appropriate backlash between gears.This will also ensure The end of the gear teeth will be with each Other. Use pure mineral oil as lubricant Recommended for most mitre gear applications.Inventory Miter gears are made of 40 carbon steel. "M" series provide unhardened ordinary holes. The "HM" series are equipped with hardened teeth with flat holes. "HMK" series are equipped with hardened teeth with keyway And fixing screws for mounting on the shaft. Hardened helical gears have about 50% or more Horsepower capacity and provide greater gear wear Than untreated gears. All mitre gears are cut with a 20° pressure angle system. They will not operate with any other pressure angle system. |

Miter gear

20° pressure angle

Steel-Ordinary hole-Unhardened teeth

| Quantity |

All categories |

直径 |

Face makeup |

Aperture (inch) |

Installation method |

Wheel hub (inch) |

Weight pounds. |

|

tooth |

Quantity |

Pitch | outside |

(Inches) |

Diameter I length |

(Inches) |

直径 Project (application.) |

(App.) |

4 pitch

|

24 |

M424 |

6.00 |

6.36 |

1.33 |

11/2 |

3 9/16 |

5 1/2 |

4 |

1 15 / 16 |

14.4 |

|

24 |

M424A |

6.00 |

6.36 |

1.33 |

13/4 |

3 9/16 |

5 1/2 |

4 |

1 15 / 16 |

13.7 |

|

28 |

M428 |

7.00 |

7.36 |

1.43 |

2 |

3 5/8 |

6 |

5 |

1 15 / 16 |

21.1 |

5 pitch

|

25 |

M525 |

5.00 |

5.29 |

1.10 |

1 3 / 8 |

3 |

Zones |

3 1/2 |

13/4 |

8.5 |

|

25 |

M525A |

5.00 |

5.29 |

1.10 |

1 1 / 2 |

3 |

Zones |

3 1/2 |

13/4 |

8.3 |

|

25 |

M525B |

5.00 |

5.29 |

1.10 |

1 3 / 4 |

3 |

Zones |

3 1/2 |

13/4 |

7.8 |

6 pitch

|

24 |

M624 |

4.00 |

4.24 |

. 86 |

1 1/4 |

2 15/16 |

4 5/8 |

3 |

15/16 |

4.4 |

|

24 |

M624A |

4.00 |

4.24 |

. 86 |

1 1/2 |

2 15/16 |

4 5/8 |

3 |

15/16 |

4.3 |

|

27 |

M627 |

4.50 |

4.74 |

. 96 |

1 1/4 |

2 5/8 |

4 1/8 |

31/4 |

11/2 |

6.3 |

|

27 |

M627A |

4.50 |

4.74 |

. 96 |

1 1/2 |

2 5/8 |

4 1/8 |

31/4 |

11/2 |

5.9 |

8 pitch

|

24 24 24 |

M824 |

3.00 |

3.18 |

. 64 |

3/4 |

1 37 / 64 |

29/16 |

13/4 |

13/16 |

1.5 |

|

28 |

M828 |

3.50 |

3.68 |

. 75 |

1 |

2 3/32 |

31/4 |

21/2 |

11/4 |

2.9 |

|

28 |

M828A |

3.50 |

3.68 |

. 75 |

1 3/16 |

2 3/32 |

31/4 |

21/2 |

11/4 |

2.8 |

|

28 |

M328B |

3.50 |

3.68 |

. 75 |

1 1/4 |

2 3/32 |

31/4 |

21/2 |

11/4 |

2.6 |

|

32 |

M832 |

4.00 |

4.18 |

. 84 |

1 |

2 3/32 |

35/8 |

3 |

11/8 |

4.8 |

10 pitch

| 20 |

M1020A |

2.00 |

2.14 |

. 44 |

1/2 |

123/64 |

2 |

15/8 |

13/16 |

. 75 |

|

20 |

M1020B |

2.00 |

2.14 |

. 44 |

5/8 |

123/64 |

2 |

15/8 |

13/16 |

. 72 |

|

20 |

M1020 |

2.00 |

2.14 |

. 44 |

3/44 |

123/64 |

2 |

15/8 |

13/16 |

. 67 |

|

20 |

M1020C |

2.00 |

2.14 |

. 44 |

7/8 |

123/64 |

2 |

15/8 |

13/16 |

. 58 |

|

25 |

M1025 |

2.50 |

2.64 |

. 55 |

3/4 |

15/8 |

27/16 |

2 |

15/16 |

1.2 |

|

25 |

M1025A |

2.50 |

2.64 |

. 55 |

7/8 |

15/8 |

27/16 |

2 |

15/16 |

1.2 |

|

25 |

M1025B |

2.50 |

2.64 |

. 55 |

1 |

15/8 |

27/16 |

2 |

15/16 |

1.2 |

|

30 |

M1030 |

3.00 |

3.14 |

. 64 |

3/4 |

13/4 |

23/4 |

2 |

1 |

1.8 |

Miter gear

20° pressure angle

Steel-Ordinary hole-Unhardened teeth

| Quantity |

All categories |

直径 |

Face makeup |

Aperture (inch) |

Installation method |

Wheel hub (inch) |

Weight pounds. |

|

tooth |

Quantity |

Pitch | outer |

(Inches) |

Diameter one length |

(Inches) |

Diameter one Project (application.) |

(App.) |

12 pitch

| 15 |

M1215 |

1.25 |

1.37 |

. 27 |

3/8 |

55/64 |

1 1/4 |

1 |

1/2 |

. 17 |

|

15 |

M1215A |

1.25 |

1.37 |

. 27 |

7/16 |

55/64 |

1 1/4 |

1 |

1/2 |

. 16 |

|

15 |

M1215B |

1.25 |

1.37 |

. 27 |

1/2 |

55/64 |

1 1/4 |

1 |

1/2 |

. 15 |

|

18 |

M1218 |

1.50 |

1.62 |

. 32 |

1/2 |

1164 |

1 1/2 |

1 1/4 |

5/8 |

. 30 |

|

18 |

M1218A |

1.50 |

1.62 |

. 32 |

5/8 |

1164 |

1 1/2 |

1 1/4 |

5/8 |

. 25 |

|

18 |

M1218B |

1.50 |

1.62 |

. 32 |

3/4 |

11/64 |

1 1/2 |

1 1/4 |

5/8 |

. 22 |

|

21 |

M1221 |

1.75 |

1.87 |

. 39 |

1/2 |

13/16 |

1 3/4 |

1 3/8 |

11/16 |

. 45 |

|

21 |

M1221A |

1.75 |

1.87 |

. 39 |

9/16 |

13/16 |

1 3/4 |

1 3/8 |

11/16 |

. 45 |

|

21 |

M1221B |

1.75 |

1.87 |

. 39 |

5/8 |

13/16 |

1 3/4 |

1 3/8 |

11/16 |

. 43 |

|

21 |

M1221C |

1.75 |

1.87 |

. 39 |

3/4 |

13/16 |

1 3/4 |

1 3/8 |

11/16 |

. 38 |

|

24 |

M1224 |

2.00 |

2.12 |

. 43 |

1/2 |

17/32 |

1 7/8 |

1 1/2 |

11/16 |

. 62 |

|

30 |

M1230 |

2.50 |

2.62 |

. 54 |

5/8 |

131/64 |

2 5/16 |

1 3/4 |

27/32 |

1.10 |

14 pitch

| 14 |

M1414 |

1.00 |

1.11 |

. 19 |

3/8 |

47/64 |

1 1/16 |

7/8 |

1/2 |

. 10 |

|

14 |

M1414A |

1.00 |

1.11 |

. 19 |

7/16 |

47/64 |

1 1/16 |

7/8 |

1/2 |

. 09 |

16 pitch

| 12 |

M1612 |

. 75 |

. 84 |

. 16 |

5/16 |

37/64 |

13/16 |

5/8 |

3/8 |

. 05 |

|

16 |

M1616 |

1.00 |

1.09 |

. 22 |

3/8 |

3/4 |

1 1/16 |

3/4 |

7/16 |

. 07 |

|

20 |

M1620 |

1.25 |

1.34 |

. 27 |

7/16 |

27/32 |

1 1/4 |

1 |

1/2 |

. 16 |

|

24 |

M1624 |

1.50 |

1.59 |

. 31 |

7/8 |

7/8 |

1 3/8 |

1 |

1/2 |

. 20 |

20 pitch

| 20 |

M2020 |

1.00 |

1.07 |

. 23 |

3/8 |

13/16 |

1 1/8 |

3/4 |

1/2 |

. 06 |

|

25 |

M2025 |

1.25 |

1.32 |

. 25 |

3/8 |

3/4 |

1 3/16 |

1 |

3/8 |

. 14 |

24 pitch

| 24 |

M2424 |

1.00 |

1.06 |

. 20 |

1/4 |

9/16 |

29/32 |

5/8 |

9/32 |

. 12 |

Miter gear

20° pressure angle

Steel-smooth hole-hardened tooth

| Quantity |

All categories |

直径 |

Face makeup |

Aperture (inch) |

Installation method |

Wheel hub (inch) |

Weight pounds. |

|

tooth |

Quantity |

Pitch | outside |

(Inches) |

Diameter I length |

(Inches) |

Diameter I project (application.) |

(App.) |

4 pitch

|

24 |

HM424 |

6.00 |

6.36 |

1.33 |

11/2 |

39/16 |

51/2 |

4 |

1 15 / 16 |

14.4 |

|

28 |

HM428 |

7.00 |

7.36 |

1.43 |

2 |

35/8 |

6 |

5 |

1 15 / 16 |

21.1 |

5 pitch

|

25 |

HM525 |

5.00 |

5.29 |

1.10 |

13/8 |

3 |

45/8 |

31/2 |

13/4 |

8.5 |

|

25 |

HM525A |

5.00 |

5.29 |

1.10 |

11/2 |

3 |

45/8 |

31/2 |

13/4 |

8.3 |

|

25 |

HM525B |

5.00 |

5.29 |

1.10 |

13/4 |

3 |

45/8 |

31/2 |

13/4 |

7.5 |

6 pitch

|

24 |

HM624 |

4.00 |

4.24 |

. 86 |

11/4 |

25/16 |

35/8 |

3 |

15/16 |

4.4 |

|

24 |

HM624A |

4.00 |

4.24 |

. 86 |

11/2 |

25/16 |

35/8 |

3 |

15/16 |

4.0 |

|

27 |

HM627 |

4.50 |

4.74 |

. 96 |

11/4 |

25/8 |

41/8 |

31/4 |

11/2 |

6.3 |

|

27 |

HM627A |

4.50 |

4.74 |

. 96 |

11/2 |

25/8 |

41/8 |

31/4 |

11/2 |

5.9 |

8 pitch

|

24 24 24 |

HM824 |

3.00 |

3.18 |

. 64 |

3/4 |

137/64 |

29/16 |

13/4 |

13/16 |

2.1

2.6 |

|

28 |

HM828 |

3.50 |

3.68 |

. 75 |

1 |

23/32 |

31/4 |

21/2 |

11/4 |

3.0 |

|

28 |

HM828A |

3.50 |

3.68 |

. 75 |

13/16 |

23/32 |

31/4 |

21/2 |

11/4 |

2.8 |

|

28 |

HM828B |

3.50 |

3.68 |

. 75 |

11/4 |

23/32 |

31/4 |

21/2 |

11/4 |

2.6 |

|

32 |

HM832 |

4.00 |

4.18 |

. 85 |

1 |

29/32 |

35/8 |

3 |

11/8 |

4.7 |

10 pitch

|

20 20 20 20 |

HM1020A |

2.00 |

2.14 |

. 44 |

1/2 |

123/64 |

2 |

15/8 |

13/16 |

. 76 |

|

25 |

HM1025 |

2.50 |

2.64 |

. 55 |

3/4 |

15/8 |

27/16 |

2 |

15/16 |

1.3 |

|

25 |

HM1025A |

2.50 |

2.64 |

. 55 |

7/8 |

15/8 |

27/16 |

2 |

15/16 |

1.2 |

|

25 |

HM1025B |

2.50 |

2.64 |

. 55 |

1 |

15/8 |

27/16 |

2 |

15/16 |

1.2 |

|

30 |

HM1030 |

3.00 |

3.14 |

. 64 |

3/4 |

13/4 |

23/4 |

2 |

1 |

1.8 |

Helical gear 20°

pressure angle

Steel-smooth hole-hardened tooth

| Quantity |

All categories |

直径 |

Face makeup |

Aperture (inch) |

Installation method |

Wheel hub (inch) |

Weight pounds. |

|

tooth |

Quantity |

Off the court |

(Inches) |

Diameter I length |

(Inches) |

Diameter I project (application.) |

(App.) |

12 pitch

|

15 |

HM1215 |

1.25 |

1.37 |

. 27 |

3/8 |

55/64 |

11/4 |

1 |

1/2 |

. 15 |

|

15 |

HM1215B |

1.25 |

1.37 |

. 27 |

1/2 |

55/64 |

11/4 |

1 |

1/2 |

. 15 |

|

18 |

HM1218 |

1.50 |

1.62 |

. 32 |

1/2 |

11/ 64 |

11/2 |

11/4 |

5/8 |

. 30 |

|

18 |

HM1218A |

1.50 |

1.62 |

. 32 |

5/8 |

11/ 64 |

11/2 |

11/4 |

5/8 |

. 25 |

|

18 |

HM1218B |

1.50 |

1.62 |

. 32 |

3/4 |

11/ 64 |

11/2 |

11/4 |

5/8 |

. 22 |

|

21 |

HM1221 |

1.75 |

1.87 |

. 39 |

1/2 |

13/ 16 |

13/4 |

13/8 |

11/16 |

. 22 |

|

21 |

HM1221B |

1.75 |

1.87 |

. 39 |

5/8 |

13/ 16 |

13/4 |

13/8 |

11/16 |

. 42 |

|

24 |

HM1224 |

2.00 |

2.12 |

. 43 |

1/2 |

17/ 32 |

17/8 |

11/2 |

11/16 |

. 62 |

|

30 |

HM1230 |

2.50 |

2.62 |

. 54 |

5/8 |

131/ 64 |

25/ 16 |

13/4 |

27/32 |

1.1 |

14 pitch

| 14 |

HM1414 |

1.00 |

1.11 |

. 19 |

3/8 |

47/64 |

11/16 |

7/8 |

1/2 |

. 10 |

|

14 |

HM1414A |

1.00 |

1.11 |

. 19 |

7/16 |

47/64 |

11/16 |

7/8 |

1/2 |

. 10 |

16 pitch

| 16 |

HM1616 |

1.00 |

1.09 |

. 22 |

3/8 |

3/4 |

11/16 |

3/4 |

7/16 |

. 07 |

|

24 |

HM1624 |

1.50 |

1.59 |

. 31 |

1/2 |

7/8 |

13/8 |

1 |

1/2 |

. 20 |

|

24 |

HM2424 |

1.00 |

1.06 |

. 20 |

1/4 |

9/16 |

29/32 |

5/8 |

9/32 |

. 06 |

Miter gear

20° pressure angle

Steel-with keyway and fixing screws-hardened teeth

| Quantity |

All categories |

直径 |

Face makeup |

Aperture (inch) |

Installation method |

Wheel hub (inch) |

Weight pounds. |

|

tooth |

Quantity |

Pitch | outside |

(Inches) |

Diameter one length |

(Inches) |

Diameter one Project (application.) |

(App.) |

4 pitch

|

24 |

HMK424A |

6.00 |

6.36 |

1.33 |

13/4 |

39/16 |

51/2 |

4 |

115/16 |

13.7 |

|

28 |

HMK428 |

7.00 |

7.36 |

1.43 |

2 |

35/8 |

6 |

5 |

115/16 |

20.4 |

5 pitch

|

25 |

HMK525 |

5.00 |

5.29 |

1.10 |

13/4 |

3 |

45/8 |

31/2 |

13/4 |

8.5 |

|

25 |

HMK525B |

5.00 |

5.29 |

1.10 |

13/4 |

3 |

45/8 |

31/2 |

13/4 |

7.5 |

6 pitch

|

24 |

HMK624 |

4.00 |

4.24 |

. 86 |

11/4 |

25/16 |

35/8 |

3 |

15/16 |

4.4 |

|

24 |

HMK624A |

4.00 |

4.24 |

. 86 |

11/2 |

25/16 |

35/8 |

3 |

15/16 |

4.0 |

|

27 |

HMK627 |

4.50 |

4.74 |

. 96 |

11/4 |

25/8 |

41/8 |

31/4 |

11/2 |

6.3 |

|

27 |

HMK627A |

4.50 |

4.74 |

. 96 |

11/2 |

25/8 |

41/8 |

31/4 |

11/2 |

5.9 |

8 pitch

|

24 24 24 |

HMK824 |

3.00 |

3.18 |

. 64 |

3/4 |

137/64 |

29/16 |

13/4 |

13/16 1 |

1.5 |

|

28 |

HMK828 |

3.50 |

3.68 |

. 75 |

1 |

23/32 |

31/4 |

21/2 |

11/4 |

2.9 |

|

28 |

HMK828A |

3.50 |

3.68 |

. 75 |

13/16 |

23/32 |

31/4 |

21/2 |

11/4 |

2.7 |

|

28 |

HMK828B |

3.50 |

3.68 |

. 75 |

11/4 |

23/32 |

31/4 |

21/2 |

11/4 |

2.6 |

10 pitch

|

20 20 20 20 |

HMK1020A |

2.00 |

2.14 |

. 44 |

1/2 |

123/64 |

2 |

15/8 |

13/16 |

. 74 |

|

25 |

HMK1025 |

2.50 |

2.64 |

. 55 |

3/4 |

15/8 |

27/16 |

2 |

15/16 |

1.30 |

|

25 |

HMK1025A |

2.50 |

2.64 |

. 55 |

7/8 |

15/8 |

27/16 |

2 |

15/16 |

1.20 |

|

25 |

HMK1025B |

2.50 |

2.64 |

. 55 |

1 |

15/8 |

27/16 |

2 |

15/16 |

1.10 |

12 pitch

| 15 |

HMK1215B |

1.25 |

1.37 |

. 27 |

1/2 |

55/64 |

11/4 |

1 |

1/2 |

. 14 |

|

18 |

HMK1218A |

1.50 |

1.62 |

. 32 |

5/8 |

11/64 |

11/2 |

11/4 |

5/8 |

. 25 |

|

21 |

HMK1221B |

1.75 |

1.87 |

. 39 |

5/8 |

13/16 |

13/4 |

13/8 |

11/16 |

. 41 |

|

30 |

HMK1230 |

2.50 |

2.62 |

. 54 |

5/8 |

131/64 |

2 5/16 |

13/4 |

27/32 |

1.1 |

16 pitch

| 16 |

HMK1616 |

1.00 |

1.09 |

. 22 |

3/8 |

3/4 |

11/16 |

3/4 |

7/16 |

. 07 |

|

24 |

HMK1624 |

1.50 |

1.59 |

. 31 |

1/2 |

7/8 |

13/8 |

1 |

1/2 |

. 20 |

Miter gear

Horsepower rating

steel

| All categories |

Revolutions per minute |

|||||||||

|

Quantity |

10 |

25 |

50 |

100 |

200 |

300 |

600 |

900 |

1200 |

1800 |

|

M424 |

. 80 |

1.90 |

3.6 |

6.4 |

10.6 |

13.5 |

18.8 |

21.5 |

23.0 |

|

|

HM424 |

1.40 |

3.33 |

6.3 |

11.2 |

18.6 |

23.6 |

33.0 |

38.0 |

40.0 |

|

|

M428 |

1.07 |

2.50 |

4.8 |

8.4 |

13.6 |

17.2 |

23.3 |

26.5 |

28.5 |

|

|

HM428 |

1.90 |

4.50 |

8.4 |

14.7 |

23.8 |

30.0 |

40.0 |

46.0 |

50.0 |

|

|

M525 |

. 45 |

1.05 |

2.0 |

3.7 |

6.3 |

8.1 |

11.6 |

13.6 |

15.0 |

|

|

HM525 |

. 75 |

1.90 |

3.6 |

6.5 |

11.0 |

14.2 |

20.0 |

24.0 |

26.0 |

|

|

M624 |

. 25 |

. 55 |

1.1 |

2.0 |

3.5 |

4.6 |

6.9 |

8.2 |

19.0 |

10.2 |

|

HM624 |

. 40 |

1.00 |

1.9 |

3.5 |

6.1 |

8.0 |

12.0 |

14.5 |

16.0 |

18.0 |

|

M627 |

. 30 |

. 75 |

1.4 |

2.5 |

4.3 |

5.7 |

8.5 |

9.9 |

11.0 |

12.0 |

|

HM627 |

. 50 |

1.33 |

2.5 |

4.4 |

7.5 |

10.0 |

1.5 |

17.5 |

19.0 |

21.0 |

|

M824 |

. 10 |

. 25 |

.5 |

.9 |

1.5 |

2.1 |

3.3 |

4.0 |

4.5 |

5.3 |

|

HM824 |

. 20 |

. 40 |

.8 |

1.5 |

2.6 |

3.7 |

5.8 |

7.0 |

8.0 |

9.3 |

|

M828 |

. 15 |

. 33 |

.7 |

1.2 |

2.2 |

2.9 |

4.4 |

5.3 |

6.0 |

6.8 |

|

HM828 |

. 25 |

. 60 |

1.2 |

2.1 |

3.9 |

5.0 |

7.7 |

9.3 |

10.5 |

12.0 |

|

M832 |

. 20 |

. 45 |

.9 |

1.6 |

2.8 |

3.7 |

5.5 |

6.5 |

7.2 |

8.0 |

|

HM832 |

. 33 |

. 80 |

1.5 |

2.8 |

4.9 |

6.5 |

9.6 |

11.4 |

12.5 |

14.2 |

|

M1020 |

. 03 |

. 08 |

.2 |

.3 |

.6 |

.8 |

1.3 |

1.7 |

2.0 |

2.4 |

|

HM1020 |

. 05 |

. 15 |

.3 |

.5 |

1.0 |

1.4 |

2.3 |

3.0 |

3.5 |

4.2 |

|

M1025 |

. 06 |

. 15 |

.3 |

.5 |

.9 |

1.3 |

2.0 |

2.5 |

2.9 |

3.5 |

|

HM1025 |

. 10 |

. 25 |

.5 |

.9 |

1.6 |

2.3 |

3.5 |

4.4 |

5.0 |

6.0 |

|

M1030 |

. 08 |

. 20 |

.4 |

.7 |

1.3 |

1.8 |

2.8 |

3.5 |

3.9 |

4.5 |

|

HM1030 |

. 15 |

. 33 |

.7 |

1.3 |

2.3 |

3.2 |

4.9 |

6.1 |

6.8 |

8.0 |

|

M1215 |

. 01 |

. 02 |

. 05 |

. 10 |

. 20 |

.3 |

.5 |

.6 |

.8 |

.9 |

|

HM1215 |

. 02 |

. 04 |

. 10 |

. 17 |

. 33 |

.4 |

.8 |

1.0 |

1.3 |

1.6 |

|

M1218 |

. 01 |

. 03 |

. 08 |

. 14 |

. 25 |

.4 |

.7 |

.9 |

1.0 |

1.3 |

|

HM1218 |

. 02 |

. 05 |

. 15 |

. 25 |

. 47 |

.7 |

1.1 |

1.5 |

1.8 |

2.2 |

|

M1221 |

. 02 |

. 05 |

. 11 |

. 20 |

. 40 |

.5 |

.9 |

1.2 |

1.4 |

1.7 |

|

HM1221 |

. 04 |

. 10 |

. 20 |

. 33 |

. 70 |

1.0 |

1.6 |

2.1 |

2.5 |

3.0 |

|

M1224 |

. 03 |

. 07 |

. 15 |

. 25 |

. 50 |

.7 |

1.2 |

1.5 |

1.7 |

2.0 |

|

HM1224 |

. 05 |

. 12 |

. 25 |

. 47 |

. 90 |

1.2 |

2.1 |

2.6 |

3.0 |

3.5 |

|

M1230 |

. 05 |

. 12 |

. 25 |

. 44 |

. 80 |

1.1 |

1.8 |

2.2 |

2.5 |

3.0 |

|

HM1230 |

. 09 |

. 21 |

. 40 |

. 75 |

1.40 |

1.9 |

3.2 |

4.0 |

4.4 |

5.3 |

|

M1414 |

|

. 01 |

. 02 |

. 05 |

. 09 |

.1 |

.2 |

.3 |

.4 |

.5 |

|

HM1414 |

|

. 02 |

. 04 |

. 09 |

. 16 |

.2 |

.4 |

.6 |

.7 |

.9 |

|

M1616 |

|

. 01 |

. 02 |

. 05 |

. 09 |

.1 |

.2 |

.3 |

.4 |

.5 |

|

HM1616 |

|

. 02 |

. 04 |

. 09 |

. 16 |

.2 |

.4 |

.6 |

.7 |

.9 |

|

M1620 |

|

. 02 |

. 04 |

. 08 |

. 14 |

.2 |

.4 |

.5 |

.6 |

.8 |

|

HM1620 |

|

. 04 |

. 07 |

. 15 |

. 25 |

.4 |

.7 |

.9 |

1.0 |

1.3 |

|

M1624 |

|

. 03 |

. 06 |

. 12 |

. 20 |

.3 |

.5 |

.7 |

.8 |

1.0 |

|

HM1624 |

|

. 05 |

. 10 |

. 21 |

. 40 |

.5 |

.9 |

1.2 |

1.4 |

1.8 |

|

M2020 |

|

. 01 |

. 02 |

. 04 |

. 08 |

.1 |

.2 |

.2 |

.4 |

.5 |

|

HM2020 |

|

. 02 |

. 04 |

. 07 |

. 14 |

.2 |

.4 |

.5 |

.6 |

.8 |

|

M2025 |

|

. 02 |

. 03 |

. 06 |

. 12 |

.2 |

.3 |

.4 |

.5 |

.6 |

|

HM2025 |

|

. 04 |

. 05 |

. 10 |

. 21 |

.3 |

.5 |

.7 |

.9 |

1.0 |

The rating listed to the right of the black line exceeds the recommended pitch line speed.

before: European standards

Next: No Information